@lyse Great job!

I suggested it because I did it in the past, but never used it on bigger works.

In my case I did it exclusively on really small projects and used a thin rubber head hammer to prevent deforming the metal.

Recent posts in reply to #72pp3ya

@lyse Great job!

I suggested it because I did it in the past, but never used it on bigger works.

In my case I did it exclusively on really small projects and used a thin rubber head hammer to prevent deforming the metal.

@alexonit Thanks mate! Ah cool, now I'm curious, what did you make? :-)

You used the rubber hammer to fold the metal, not to set the rivets, right? :-? I glued cork on my wooden mallet some time ago. This worked quite good for bending. But rubber might be even better as it is a tad softer. I will try this next time, I think I have one deep down in a drawer somewhere.

@lyse In my case it was a silver necklace, a hummingbird with a wing connected with the cold welding I mentioned using thin brass wires.

It made it in a goldsmithing class (I went to a private craftmanship high-school) so no phones allowed (no photos of it) and no "take home" of the works.

Here's a rough sketch of it drawn by memory, the dots in the wing is where it connects to the body.

The technique is basically the same as i described, but the scale is much smaller, the whole piece was about 5-6 cm on the largest side.

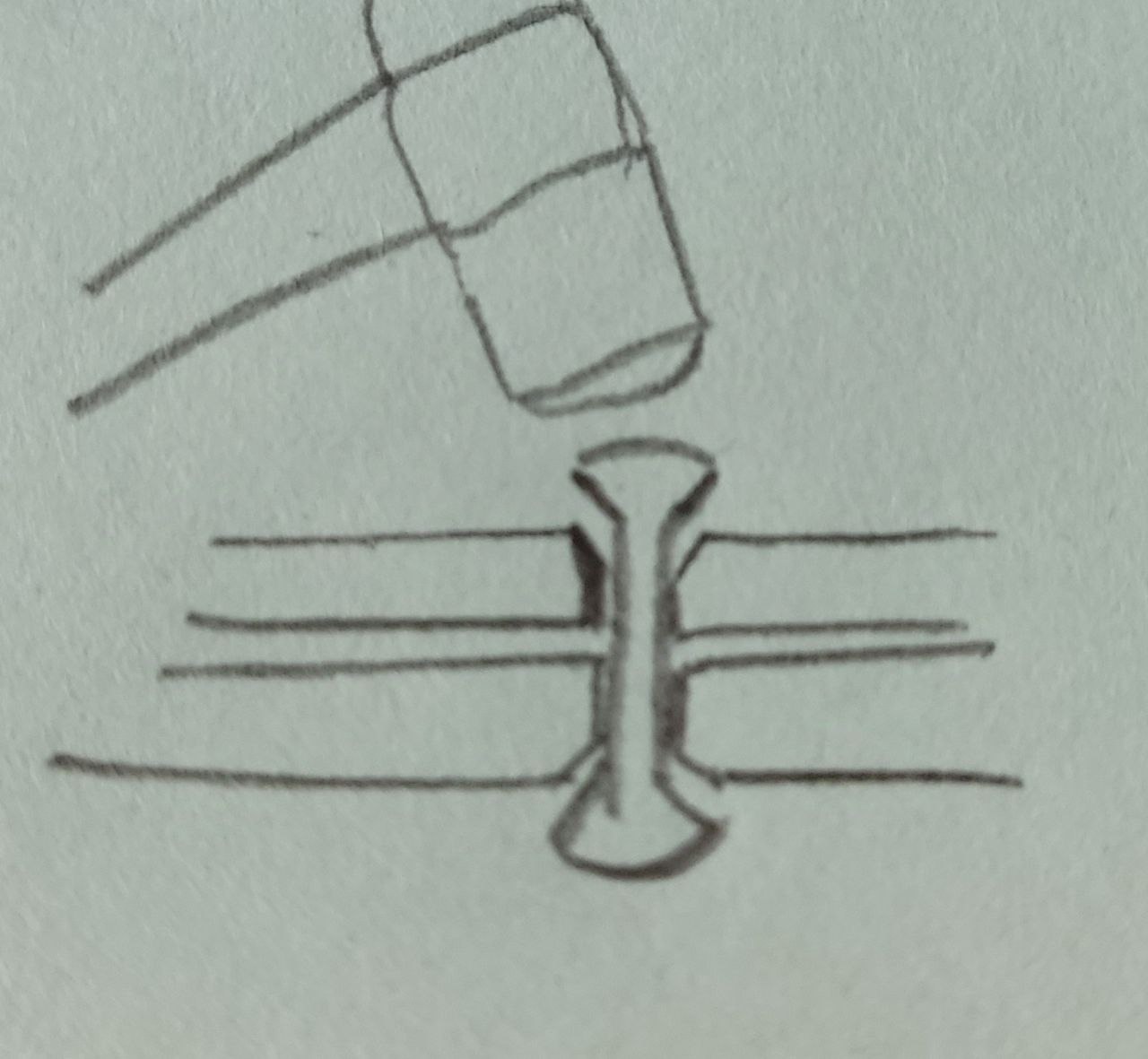

The rivet was made by drilling a hole through the parts, than with a short and thicker drill you widen the hole on the surface to let the rivet settle flatter on the piece, then with a rubber hammer you hit it to flatten the head until it's snug on the hole, lock them together by doing the same on the other side.

Note that widening the hole with a thicker drill head won't make a difference with bigger holes, mine had holes of about 1-2 mm of diameter maximum.

Here's a sketch of what is going on for clarity.